What are the classifications and uses of galvanized steel sheets?

What are the classifications and uses of galvanized steel sheets? Let's take a look at the following points.Production and processing of galvanized steel sheet

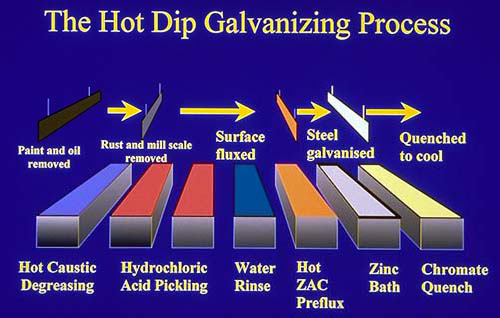

According to production and processing methods. galvanized steel sheets can be divided into the following categories:1. Hot dip galvanized steel sheet. The steel sheet is immersed in a molten zinc bath to adhere a zinc-plated steel sheet to the surface. At present, it is mainly produced by a continuous galvanizing process, that is, a coiled steel plate is continuously immersed in a plating tank in which zinc is melted to form a galvanized steel sheet.

2. Alloyed galvanized steel sheet. This steel sheet is also produced by hot dip, but immediately after it is taken out, it is heated to about 500 ° C to form an alloy coating of zinc and iron. This galvanized sheet has good adhesion and weldability of the coating.

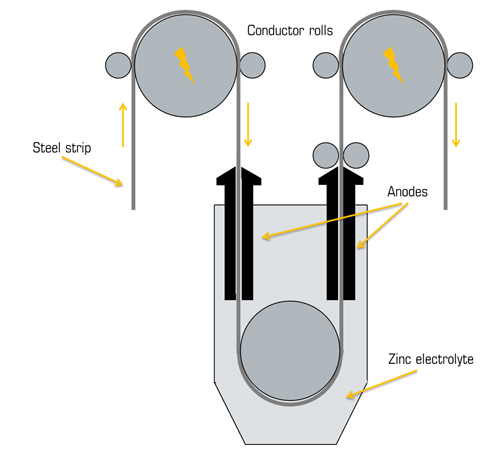

3. Electro-galvanized steel plate. The production of such a galvanized steel sheet by electroplating has good workability. However, the coating is thinner and the corrosion resistance is not as good as that of hot dip galvanized sheet.

4. Single-sided plating and double-sided differential galvanized steel. Single-sided galvanized steel, that is, a product that is only galvanized on one side. It has better adaptability than double-sided galvanized sheet in welding, painting, anti-rust treatment and processing. In order to overcome the shortcomings of uncoated zinc on one side, there is a galvanized sheet coated with a thin layer of zinc on the other side, that is, a double-sided differential galvanized sheet.

5. Alloy, composite galvanized steel sheet. It is made of zinc and other metals such as lead, zinc alloy or even composite plated steel. This steel plate has excellent rust resistance and good coating properties.

In addition to the above five types, there are also colored galvanized steel sheets, printed galvanized steel sheets, and polyvinyl chloride laminated galvanized steel sheets. However, the most commonly used ones are still hot dip galvanized sheets.Galvanized steel sheets can be further divided into galvanized steel sheets for general use, roofing, exterior panels for buildings, structural, tiled slabs, tensile and deep drawing.

Galvanized sheet is coated with zinc on the steel plate. Such steel sheet has good service life and corrosion resistance, so the use rate of galvanized sheet is now higher and higher, so which galvanized sheet is used specifically? What about?

Types of use:

Exterior construction, interior use, furniture, household appliances, substrate types, hot-dip galvanized sheet galvanized or hot-dip galvanized sheet, cold-rolled sheet or electro-galvanized sheet. At present, China's galvanizing industry has already With the rapid development, the solid form of galvanized steel can be changed, and the scope of application of galvanized steel is continuously expanded. For example, galvanized sheet steel products are mainly used in construction, light industry, and automobiles. It is precisely because there are so many classifications of galvanized sheets, so the price of galvanized sheets is somewhat different in some respects.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!