A333

A333 low temperature pipe

Spot size: 8-1240x1-200mm<1/8 "-48"xSCH5S-SCH160,STD,XS,XXSStandards: GB/T18984-2003,ASTM A333

Product material: 10MnDG,16MnDG,09DG,09Mn2VDG, 06Ni3MoDG,A333Gr1,A333Gr3,A333Gr4,A333Gr6,A333Gr7

Application: Apply to-45c~-195c levels of low temperature pressure vessel pipeline and seamless steel tube for heat exchanger pipes. Download More Details about ASTM A333

Note:

One-off success is better for welding, aluminum melt Rotary cutting tool is too low, the second heating, aluminum pipes deform easily.

Electrode must be evenly flux in order to ensure the quality of solder.

Torch flame cannot be too long, and you must use the proper temprature heat or dispersant aluminum tubes very easy to melt.

Welding, special paste for nylon two or three minutes after cooling of the pipe cement repository access, otherwise the solder easy to leak.

Welding time is not too long, because the melting point is too low for too long can easily lead to aluminium pipe melted or thinned, suppressed easily leaked.

Liner must be placed wet towels, protection in place because welding space is very cramped, so be sure to pay attention to protection of a refrigerator

Can't use torch first heated and then dipped in welding electrode powder, because the electrode melting point is too low.

Impact of temperature:

Impact of temperature:

| Impact of temperature | ||

|---|---|---|

| Level | Minimum impact test temperature℉ | ℃ |

| A333 Gr1 | -50 | -45 |

| A333 Gr3 | -150 | -100 |

| A333 Gr4 | -150 | -100 |

| A333 Gr6 | -50 | -45 |

| A333 Gr7 | -100 | -75 |

| A333 Gr8 | -320 | -195 |

| A333 Gr9 | -100 | -75 |

| A333 Gr10 | -75 | -60 |

| A333 Gr11 | -- | -- |

| 16MnDG | -- | -45 |

| 10MnDG | -- | -45 |

| 09DG | -- | -45 |

| 09Mn2VDG | -- | -70 |

| 06Ni3MoDG | -- | -100 |

Overview of process

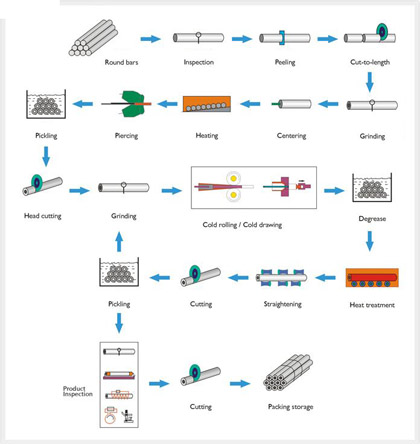

A333 low temperature pipe hot-rolled (squeeze seamless steel tubes): tube perforation → → → heated three-roll cross-rolling, continuous rolled or extruded-cannula → sizing (or reducing) steel tube straightening → → → → cooling water pressure test (or testing) → tags → storage. Drawing (rolling) seamless steel pipe: pipe perforated → heat → → → → start → annealing pickling oil (copper) → multi-pass drawing (cold rolled) steel tube heat treatment straightening → → → → hydrostatic test (testing) → tags → storage.

A333 Seamless management of weight formula:[(OD-wall thickness) *wall thickness]*0.02466=kg/meters of wall thickness (weight per meter)

| A333 Mechanical properties | ||||

|---|---|---|---|---|

| Standard | Grades | Tensile strength (Mpa) | Yield strength (Mpa) | Elongation(%) |

| ASTM A333Gr1 | ≥380 | ≥205 | ≥35 | ≥25 |

| A333Gr3 | ≥450 | ≥240 | ≥30 | ≥20 |

| A333Gr4 | ≥415 | ≥240 | ≥30 | ≥16.5 |

| A333Gr6 | ≥415 | ≥240 | ≥30 | ≥16.5 |

| A333Gr7 | ≥450 | ≥240 | ≥30 | ≥22 |

| A333Gr8 | ≥690 | ≥515 | ≥22 | -- |

| A333Gr9 | ≥435 | ≥315 | ≥28 | -- |

| A333Gr10 | ≥550 | ≥450 | ≥22 | -- |

| A333Gr11 | ≥450 | ≥240 | ≥18 | -- |

| GB/T1898 -2003 | 16MnDG | 490-665 | ≥325 | ≥30 |

| 10MnDG | ≥400 | ≥240 | ≥35 | -- |

| 09DG | ≥385 | ≥210 | ≥35 | -- |

| 09Mn2VDG | ≥450 | ≥300 | ≥30 | -- |

| 06Ni3MoDG | ≥455 | ≥250 | ≥30 | -- |

| A333 Chemical composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard | GB/T18984-2003 | ||||||||||

| Grades | C | Si | Mn | S | P | Cr | Ni | Mo | Cu | V | Al |

| 16MnDG | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | -- | -- |

| 10MnDG | ≤0.13 | 0.17-0.37 | ≤1.35 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | ≤0.07 | -- |

| 09DG | ≤0.12 | 0.17-0.37 | ≤0.95 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | ≤0.07 | -- |

| 09Mn2VDG | ≤0.12 | 0.17-0.37 | ≤1.85 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | ≤0.12 | -- |

| 06Ni3MoDG | ≤0.08 | 0.17-0.37 | ≤0.85 | ≤0.025 | ≤0.025 | -- | 2.5-3.7 | 0.15-0.30 | -- | ≤0.05 | -- |

| ASTM A333 | A333Gr1 | ≤0.30 | -- | ≤0.025 | 0.40-1.06 | ≤0.025 | -- | -- | -- | -- | -- |

| A333Gr3 | ≤0.19 | 0.18-0.37 | 0.31-0.64 | ≤0.025 | ≤0.025 | -- | 3.18-3.82 | -- | -- | -- | -- |

| A333Gr4 | ≤0.12 | 0.18-0.37 | 0.50-1.05 | ≤0.025 | ≤0.025 | 0.44-1.01 | 0.47-0.98 | -- | 0.40-0.75 | -- | 0.04-0.30 |

| A333Gr6 | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | -- | -- |

| A333Gr7 | ≤0.19 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | -- | 2.03-2.57 | -- | -- | -- | -- |

| A333Gr8 | ≤0.13 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | -- | 8.40-9.60 | -- | -- | -- | -- |

| A333Gr9 | ≤0.20 | -- | 0.40-1.06 | ≤0.025 | ≤0.025 | -- | 1.60-2.24 | -- | 0.75-1.25 | -- | -- |

| A333Gr10 | ≤0.20 | 0.10-0.35 | 1.15-1.50 | ≤0.015 | ≤0.030 | ≤0.15 | ≤0.25 | ≤0.50 | ≤0.015 | ≤0.12 | ≤0.06 |

| A333Gr11 | ≤0.10 | ≤0.035 | ≤0.60 | ≤0.025 | ≤0.025 | ≤0.50 | 35.0-37.0 | ≤0.50 | -- | -- | -- |

6 "= 6 inch od pipe , sch120= sch20 is thin-walled . sch40 is standard general wall sch80 is outside thickened, is compared with OD of 20 and 40 to thickened some, sch120 outside thickened, compared with specifications 80 also to thick of, specific parameter himself see Xia standard in the of corresponds to form. you this products requirements corresponds to of is ASTM (United States national laboratory standard), standard," A333 ". Grd6= grade 6, refers to the material level material is likewise refer to the standard level, the main design characteristics in mechanical properties, such as tensile, queries related to standard forms, you will know grd6 the grade of material parameters.

A333 steel pipe is low temperature pressure vessel pipeline.A335 higher alloy content than the A333. A333 to connect elbows to be used when we are able to provide, pipe welding process we are also very good at.

GET IN TOUCH

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!