DIN17175

DIN 17175 alloy steel pipes

Name: DIN17175/EN10216-2 Heat Resistant Seamless Steel Pipe Lines

Size (mm): O.D.: 6.0∼219.0; W.T: 1∼30; L: max 12000

Applications:Used for piping in boilers.

Other specifications in accordance with customer requirements.

Download More Details about DIN 17175

DIN 17175 alloy steel pipes are of heat resistant pipe and used for high pressure and up to 600℃, application fileds include: construction of boilers, pipe-lines, pressure vessels and equipment.

Specifications:

| OD (mm) | Wall Thickness (mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

Chemical Composition:

| Grade | Chemical Composition (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | Mo | Others | |

| St35.8 | 0.17Max | 0.10~0.35 | 0.40~0.80 | 0.040Max | 0.040Max | - | - | - | - |

| St45.8 | 0.21Max | 0.10~0.35 | 0.40~1.20 | 0.040Max | 0.040Max | - | - | - | - |

| 17Mn4 | 0.14~0.20 | 0.20~0.40 | 0.90~1.20 | 0.040Max | 0.040Max | - | 0.30Max | - | - |

| 19Mn5 | 0.17~0.22 | 0.30~0.60 | 1.00~1.30 | 0.040Max | 0.040Max | - | 0.30Max | - | - |

| 15Mo3 | 0.12~0.20 | 0.10~0.35 | 0.40~0.80 | 0.035Max | 0.035Max | - | - | 0.25~0.35 | - |

| 13CrMo910 | 0.10~0.18 | 0.10~0.35 | 0.40~0.70 | 0.035Max | 0.035Max | - | 0.70~1.10 | 0.45~0.65 | - |

| 10CrMo910 | 0.08~0.15 | 0.50Max | 0.40~0.70 | 0.035Max | 0.035Max | - | 2.00~2.50 | 0.90~1.20 | - |

| 14MoV63 | 0.10~0.18 | 0.10~0.35 | 0.40~0.70 | 0.035Max | 0.035Max | - | 0.30~0.60 | 0.50~0.70 | V: 0.22~0.32 |

| X20CrMoV121 | 0.17~0.23 | 0.50Max | 0.40~0.70 | 0.030Max | 0.030Max | 0.30~0.80 | 10.00~12.50 | 0.80~1.20 | V: 0.25~0.35 |

Mechanical properties:

| Grade | Material Number | MPa or N/mm2 | ||

|---|---|---|---|---|

| Min Yield Point | Tensile Strength | |||

| WT: 16mm Max | WT: 16- 40mm | |||

| St35.8 | 1.0305 | 235 | 225 | 360~480 |

| St45.8 | 1.0405 | - | 245 | 410~530 |

| 17Mn4 | 1.0481 | - | 275 | 460~580 |

| 19Mn5 | 1.0482 | - | 315 | 510~610 |

| 15Mo3 | 1.5415 | 275 | 275 | 450~600 |

| 13CrMo910 | 1.7335 | 295 | 295 | 440~590 |

| 10CrMo910 | 1.7380 | 285 | 285 | 450~600 |

| 14MoV63 | 1.7715 | 325 | 325 | 460~610 |

| X20CrMoV121 | 1.4922 | 490 | 490 | 690~850 |

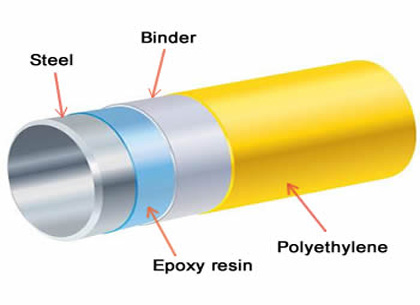

A53 carbon steel pipe is the most common carbon steel, widely used on customer demand for steel products used. A106 higher alloy content than the A53. Pipe connections are frequently used to pipe fittings, such as three-way. Steel corrosion helps a lot in life.

GET IN TOUCH

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!