Features and production process of stainless steel seamless pipe

The stainless steel seamless pipe is a long strip of steel with a hollow section and no seams around it.

Stainless steel seamless pipe features:

First, the thicker the wall thickness of the product, the more economical and practical it is. The thinner the wall thickness, the higher the processing cost will be. Secondly, the process of the product determines its limited performance. Seamless steel tube has low precision: uneven wall thickness, low brightness inside and outside the tube, high fixed-length cost, and pitting on the inside and outside, black spots are not easy to remove; third, its detection and shaping must be processed off-line so it is at high pressure , high strength, mechanical structural materials reflect its superiority.Production process of stainless steel pipes:

The rolling method is divided into hot rolling, hot extrusion and cold drawing (rolling) of stainless steel pipes.According to the stainless steel metallographic structure, it is divided into semi-ferritic semi-Martensitic stainless steel pipes, martensitic stainless steel pipes, austenitic stainless steel pipes, austenitic-ferritic iron stainless steel pipes.

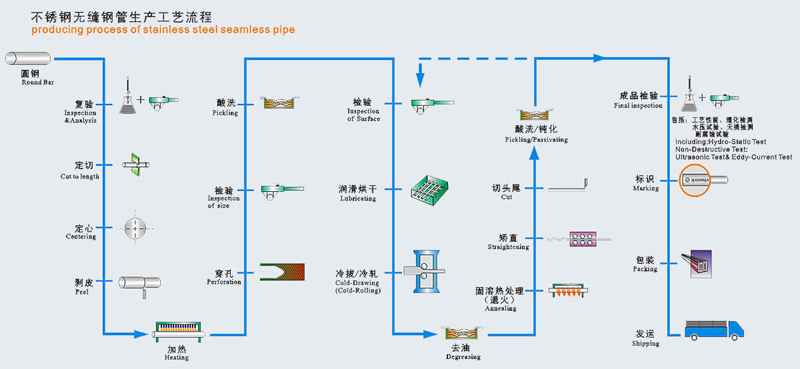

Produce Process flow

pipe blank - inspection - stripping - inspection - heating - perforation - pickling - grinding - lubrication drying - welding head - cold drawing - solution treatment - pickling - pickling passivation - inspection - cold rolling - degreasing - cutting head - Air Drying - Internal Polishing - External Polishing - Inspection - Marking - Finished Packaging

Manufacturing process

Hot rolling, cold drawing, hot expansionAccording to different production methods, it can be divided into hot rolled pipe, cold rolled pipe, cold drawn pipe and extruded pipe.

1. Hot rolled seamless pipes are generally produced on automatic rolling mills. The solid tube blank is inspected and the surface defects are removed, cut into the required length, centered on the end face of the perforated end of the tube blank, then sent to a heating furnace for heating and perforated on the punching machine. At the same time, the perforation is continuously rotated and advanced. Under the action of the roll and the head, a cavity is gradually formed inside the tube blank, which is called a capillary tube. It is sent to the automatic pipe mill for further rolling. Finally, the whole machine is uniform in wall thickness, and the sizing machine is sizing to meet the specification. The production of hot-rolled seamless steel tubes by continuous rolling mills is a more advanced method.

2. if you want to obtain a smaller size and better quality seamless pipe, you must use cold rolling, cold drawing or a combination of the two. Cold rolling is usually carried out on a two-roll mill in which the steel pipe is rolled in an annular hole formed by a variable-section circular hole groove and a stationary tapered head. Cold drawing is usually carried out on a single-chain or double-chain cold drawing machine of 0.5 to 100T.

3. Extrusion the pipe blank to be heated is placed in a closed extrusion cylinder, and the perforated rod moves together with the extrusion rod to extrude the extrusion from the smaller mold hole. This method can produce steel pipes with smaller diameters.

GET IN TOUCH

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!