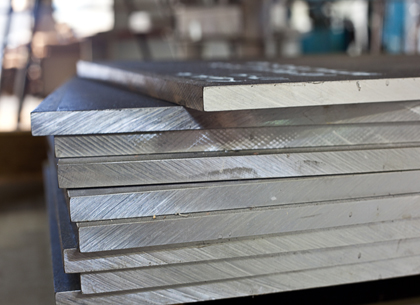

stainless steel plate

SURFACE FINISH

2B: Those finished,after cold rolling,by heat treatment,pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster.BA: Those processed with bright heat treatment after cold rolling.

NO.1: The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling.

NO.3: Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001.

NO.4: Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001.

Stainless steel is stainless steel and acid-resistant steel in General. Stainless steel plate refers to the atmosphere, steam and water, weak corrosion of steel plate, and acid-resistant steel plate refers to acid, alkali, salt and other chemical erosion corrosion of steel. They are also used in the industry of pellet machine making.

Performance

- Corrosion resistance: Stainless steel 304 and instability of NI-CR alloy similar to the ability to resist corrosion. Level of chromium carbide long heating in the temperature range may affect the alloy 321 and 347 in harsh corrosive media. Mainly used for high temperature applications, high temperature applications have high resistance of sensitized material, to avoid intergranular corrosion at lower temperatures.

- High temperature oxidation resistance: Stainless steel has a high temperature and oxidation resistance, however, oxidation rates are affected by exposure to environmental and natural factors such as product impact.

| Thickness | Permissible deviations | Width | ||

|---|---|---|---|---|

| Ceiling | Lower limit | ≤1000 | >1000~≤1300 | |

| 0.10 | 0.03 | 0.03 | ||

| 0.15 | 0.04 | 0.04 | ||

| 0.20 | 0.05 | 0.05 | ||

| 0.25 | 0.05 | 0.05 | ||

| 0.30 | 0.03 | --- | ||

| 0.40 | 0.04 | 0.04 | ||

| 0.50 | 0.08 | 0.08 | ||

| 0.50 | 0.045 | 0.05 | ||

| 0.60 | 0.05 | 0.05 | ||

| 0.75 | 0.10 | 0.10 | ||

| 0.80 | 0.05 | 0.05 | ||

| 1.00 | 0.13 | 0.13 | ||

| 1.00 | 0.055 | 0.06 | ||

| 1.20 | 0.08 | 0.08 | ||

| 1.25 | 0.13 | 0.13 | ||

| 1.50 | 0.08 | 0.08 | ||

| 1.75 | 0.15 | 0.15 | ||

| 2.00 | 0.18 | 0.18 | ||

| 2.00 | 0.10 | 0.10 | ||

| 2.25 | 0.20 | 0.20 | ||

| 2.50 | 0.23 | 0.23 | ||

| 2.50 | 0.10 | 0.11 | ||

| 2.75 | 0.25 | 0.25 | ||

| 3.00 | 0.25 | 0.25 | ||

| 3.00 | 0.13 | 0.13 | ||

| 3.25 | 0.30 | 0.30 | ||

| 3.50 | 0.30 | 0.30 | ||

| 3.75 | 0.36 | 0.36 | ||

| 4.00 | 0.36 | 0.36 | ||

| 4.00 | 0.17 | 0.17 | ||

| 4.99 | 0.36 | 0.36 | ||

| 5.00 | 0.17 | 0.17 | ||

| 6.00 | 0.17 | 0.20 | ||

| 8.00 | 0.17 | 0.22 | ||

carbon(c)

Improved blade deformation resistance and tensile strengthIncrease the hardness and improve abrasion resistance

chromium (Cr)

Increase the hardness, tensile strength and impact toughnessWear and corrosion protection

cobalt(Co)

Increased hardness and strength, so that it can withstand high-temperature quenchingUsed in alloys to strengthen other elements in more complex characteristics of individuals

copper (Cu)

Enhanced corrosion resistanceEnhanced wear-resistant

(Mn)

Increase the hardenability, wear resistance and tensile strengthSeparated from the molten metal to oxidation and separation of vaporization away oxygen

When large amounts of added, increase the hardness, but the brittle

(Mo)

Enhanced strength, hardness, hardenability and toughnessImprovement of machinability and corrosion resistance

(p)

Enhanced strength, machinability and hardnessConcentration of large easily broken

(Si)

Enhanced scalabilityIncreases tensile strength

Separated from the molten metal to oxidation and separation of vaporization away oxygen

(v)

Increases strength,hardness,and seismic capacityPrevent particles

(Ni)Enhanced strength, hardness, and corrosion resistance

(s)Use improved machinability

(w)Increases strength, hardness and toughness

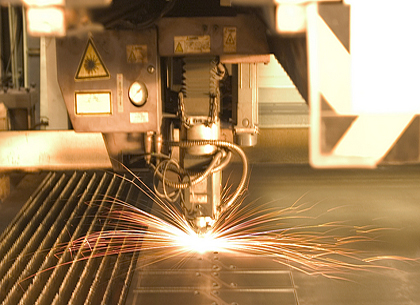

High alloy content of stainless steel plate, the price is relatively expensive. Products in corrosion resistance, acid and alkali-resistant are better than S572Gr50. High alloy content does not affect the processing of the product such as we cut and roll.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!