A335

ASTM A335 MANUFACTURING PROCESS

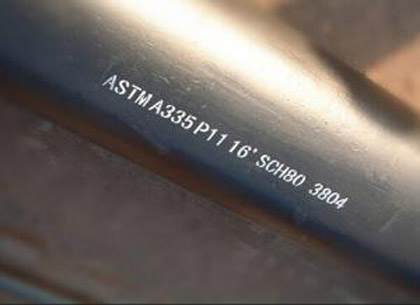

ASTM A335 hot-rolled (squeeze seamless steel tubes): round tube perforation → → → heated three-roll cross rolling, continuous rolled or extruded-cannula → sizing (or reducing) the straightening → → → cooling water pressure test (or testing) → tags → storageASTM A335 cold drawing (rolling) seamless steel pipe: round tube perforated → heat → → → → start → annealing pickling oil (copper) → multi-pass drawing (cold rolled) steel tube heat treatment straightening → → → → hydrostatic test (testing) → tags → storage Download More Details about ASTM A335

Steel, the first two digits indicate the carbon content of the steel, expressed in average carbon content per couple, for example, 40Cr.

The main alloying elements in steel, with the exception of individual micro-alloying elements, generally expressed as a percentage.

Steel vanadium v, TI Ti, aluminum alloy elements such as AL, boron b, re RE, are micro-alloying elements, although the content is low, should still be marked out in the steel.

High quality steel in steel add "a", to distinguish them from General steel.

Special-purpose alloy structural steel, steel named (or suffix) symbols that represent the steel use.

Alloy steel pipe material:16-50Mn、27SiMn、40Cr、Cr5Mo、12Cr1MoV、12Cr1MovG、15CrMo、15CrMoG、15CrMoV、13CrMo44、T91、27SiMn、25CrMo、30CrMo、35CrMo、35CrMoV、40CrMo、45CrMo、Cr9Mo、10CrMo910、15Mo3、A335P11、P22、P91、T91、102、ST45.8-111、A106B.

SA-335P92 materials are United States steel ASTM A335 P92, martensite type heat-resisting steel, in recent years more used in thermal power plants, main is main steam and reheat steam piping. Main alloy component is Cr:9%,Mo:1%, and so on. Available in ultra-supercritical units, above 600 degrees Celsius.

SA-335P92 steel is in SA-335P91 steel of based Shang, appropriate reduced has Mo elements of content, while joined has must volume of w, will material of Mo equivalent (Mo+0.5W) from P91 steel of 1% improve to about 1.5%, the steel also joined has trace of boron, by above alloy of improved Hou, and 9%Cr series of other common steel compared, its resistance high temperature corrosion and anti-oxidation performance similar, but high temperature strength and creep degeneration can get has improve.

What is the difference SA-335P91 and SA-335P92?

SA-335P91 is a Martensitic alloy steel, high temperature and high pressure, and is generally used in high temperature and high pressure power plant on the main. ASME or ASTM standards can be found inside.SA-335P92 materials are United States steel ASTM A335 P92, martensite type heat-resisting steel, in recent years more used in thermal power plants, main is main steam and reheat steam piping. Main alloy component is Cr:9%,Mo:1%, and so on. Available in ultra-supercritical units, above 600 degrees Celsius.

SA-335P92 steel is in SA-335P91 steel of based Shang, appropriate reduced has Mo elements of content, while joined has must volume of w, will material of Mo equivalent (Mo+0.5W) from P91 steel of 1% improve to about 1.5%, the steel also joined has trace of boron, by above alloy of improved Hou, and 9%Cr series of other common steel compared, its resistance high temperature corrosion and anti-oxidation performance similar, but high temperature strength and creep degeneration can get has improve.

ASTM A335 Alloy steel pipe specifications

| 4*1/6-14*1-3 | 38*5.5 | 89*5 | 133*18 |

| 14*3.5 | 42*3 | 89*5.5 | 159*6 |

| 14*4 | 42*3.5 | 89*6 | 159*6.5 |

| 16*3 | 42*4 | 89*7 | 159*7 |

| 18*2 | 42*5 | 89*7.5 | 159*8 |

| 18*3 | 42*6 | 89*8 | 159*9.5 |

| 18*4 | 42*8 | 89*9 | 159*10 |

| 18*5 | 45*3 | 89*10 | 159*12 |

| 19*2 | 45*4 | 89*11 | 159*14 |

| 21*4 | 45*5 | 89*12 | 159*16 |

| 22*2.5 | 45*6 | 108*4.5 | 159*18 |

| 22*3 | 45*7 | 108*5 | 159*20 |

| 22*4 | 48*4 | 108*6 | 159*28 |

| 22*5 | 48*4.5 | 108*7 | 168*6 |

| 25*2.5 | 48*5 | 108*8 | 168*7 |

| 25*3 | 48*6 | 108*9 | 168*8 |

| 25*4 | 48*7 | 108*10 | 168*9.5 |

| 25*5 | 48.3*12.5 | 108*12 | 168*10 |

| 25*5.5 | 51*3 | 108*14 | 168*11 |

| 27*3.5 | 51*3.5 | 108*15 | 168*12 |

| 27*4 | 51*4 | 108*16 | 168*14 |

| 27*5 | 51*5 | 108*20 | 168*15 |

| 27*5.5 | 51*6 | 114*5 | 168*16 |

| 28*2.5 | 57*4 | 114*6 | 168*18 |

| 28*3 | 57*5 | 114*7 | 168*20 |

| 28*3.5 | 57*5.5 | 114*8 | 168*22 |

| 28*4 | 57*6 | 114*8.5 | 168*25 |

| 30*2.5 | 60*4 | 114*9 | 168*28 |

| 32*2.5 | 60*4 | 114*10 | 180*10 |

| 32*3 | 60*5 | 114*11 | 194*10 |

| 32*3.5 | 60*6 | 114*12 | 194*12 |

| 32*4 | 60*7 | 114*13 | 194*14 |

| 32*4.5 | 60*8 | 114*14 | 194*16 |

| 32*5 | 60*9 | 114*16 | 194*18 |

| 34*3 | 60*10 | 114*18 | 194*20 |

| 34*4 | 76*4.5 | 133*5 | 194*26 |

| 34*4.5 | 76*5 | 133*6 | 219*6.5 |

| 34*5 | 76*6 | 133*7 | 219*7 |

| 34*6.5 | 76*7 | 133*8 | 219*8 |

| 38*3 | 76*8 | 133*10 | 219*9 |

| 38*3.5 | 76*9 | 133*12 | 219*10 |

| 38*4 | 76*10 | 133*13 | 219*12 |

| 38*4.5 | 89*4 | 133*14 | 219*13 |

| 38*5 | 89*4.5 | 133*16 | 219*14 |

| 219*16 | 273*36 | 356*28 | 426*12 |

| 219*18 | 273*40 | 356*36 | 426*13 |

| 219*20 | 273*42 | 377*9 | 426*14 |

| 219*22 | 273*45 | 377*10 | 426*17 |

| 219*24 | 298.5*36 | 377*12 | 426*20 |

| 219*25 | 325*8 | 377*14 | 426*22 |

| 219*26 | 325*9 | 377*15 | 426*30 |

| 219*28 | 325*10 | 377*16 | 426*36 |

| 219*30 | 325*11 | 377*18 | 426*40 |

| 219*32 | 325*12 | 377*20 | 426*50 |

| 219*35 | 325*13 | 377*22 | 457*9.5 |

| 219*38 | 325*14 | 377*25 | 457*14 |

| 273*7 | 325*15 | 377*32 | 457*16 |

| 273*8 | 325*16 | 377*36 | 457*19 |

| 273*9 | 325*17 | 377*40 | 457*24 |

| 273*9.5 | 325*18 | 377*45 | 457*65 |

| 273*10 | 325*20 | 377*50 | 508*13 |

| 273*11 | 325*22 | 406*9.5 | 508*16 |

| 273*12 | 325*23 | 406*11 | 508*20 |

| 273*13 | 325*25 | 406*13 | 508*22 |

| 273*15 | 325*28 | 406*17 | 558.8*14 |

| 273*16 | 325*30 | 406*22 | 530*13 |

| 273*18 | 325*32 | 406*32 | 530*20 |

| 273*20 | 325*36 | 406*36 | 570*12.5 |

| 273*22 | 325*40 | 406*40 | 610*13 |

| 273*25 | 325*45 | 406*55 | 610*18 |

| 273*28 | 356*9.5 | 406.4*50 | 610*78 |

| 273*30 | 356*12 | 406.4*55 | 624*14.2 |

| 273*32 | 356*15 | 406*60 | 824*16.5 |

| 273*35 | 356*19 |

SA-335P91 is a Martensitic alloy steel, high temperature and high pressure. A335 higher alloy content than the A333. A335 to connect flange to be used when we are able to provide, pipe welding process we are also very good at.

GET IN TOUCH

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!