Introduction of weathering resistant steel and it's application

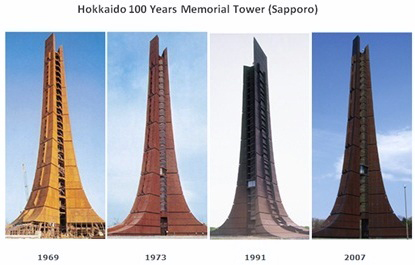

Weathering Steel, as known as Weather/Atmospheric Corrosion Resistant Steel, as a new generation of advanced steel materials, has an atmospheric corrosion resistance of 2 to 5 times that of ordinary carbon steel, and the longer the use time, the more outstanding the corrosion resistance. Due to its characteristics of rust resistance, coating-free, thinning and reducing consumption, labor saving and energy saving, it can be applied to steel structures used for long-term exposure to the atmosphere such as buildings, vehicles, bridges, towers, etc. It can also be used to manufacture containers and railways. Structural parts such as vehicles, oil derricks, seaport buildings, and oil platforms.

Overview of weathering steel

It is characterized in that the alloy composition and the weight percentage content of the weathering steel are: C: ≤ 0.12, Si: 0.25 to 0.75, Mn: 0.2 to 0.5, S ≤ 0.02, P: 0.06 to 0.12, Cu: 0.25 to 0.5, Cr: 0.3~1.25, Ni: 0.12~0.65, the rest are Fe and trace elements. By alloying Cu, Mn, Si, Al, etc., and simply adjusting the partial element content of ordinary low carbon steel (Q235 steel), it can produce good atmospheric corrosion resistance without changing the production process conditions of Q235 steel. Economic weathering steel with comprehensive mechanical properties.Weathering steel (ie, atmospheric corrosion resistant steel) is one of the series of steel grades at the forefront of the world's super steel technology after being integrated into modern metallurgical new mechanisms, new technologies and new processes. Weathering steel is made of ordinary carbon steel with a small amount of corrosion-resistant elements such as copper and nickel. It has the characteristics of high-quality steel such as toughness, plastic elongation, forming, welding, abrasion, high temperature and fatigue. The weather resistance is 2~ of carbon steel. 8 times, the coating is 1.5 to 10 times that of ordinary carbon steel, which can be used for thinning, bare use or simplified painting. The steel grade has the characteristics of rust resistance, corrosion resistance, longevity, thinning and reducing consumption, saving labor and energy, and benefiting component manufacturers and users. Weathering steel products are used to manufacture structural parts such as containers for containers containing hydrogen sulfide and corrosive media in containers, railway vehicles, oil derricks, seaport buildings, oil production platforms and chemical petroleum equipment.

Weathering steel characteristics

It refers to a low-alloy structural steel with a protective rust layer resistant to atmospheric corrosion and can be used to manufacture steel structures such as vehicles, bridges, towers, and containers. Compared with plain carbon steel, weathering steel has better corrosion resistance in the atmosphere. Compared with stainless steel, weathering steel has only a small amount of alloying elements, such as phosphorus, copper, chromium, nickel, molybdenum, niobium, vanadium, titanium, etc., the total amount of alloying elements is only a few percent, not like stainless steel, reaching 100 More than a dozen, so the price is relatively low.

Weathering steel manufacturing process

Weathering steel is generally used in the furnace-smelting (converter, electric furnace-microalloying treatment-argon-LF refining-low superheat continuous casting (feeding rare earth wire)-controlled rolling and cooling). The scrap steel is added into the furnace together with the charge, and is smelted according to a conventional process. After the steel is discharged, the deoxidizer and the alloy are added. After the molten steel is subjected to argon blowing treatment, the molten steel is immediately cast, and the molten steel after the argon temperature adjustment is cast into a slab by a continuous casting machine. The rare earth element is added to the steel, the weathering steel is purified, and the inclusion content is greatly reduced.Weathering steel application

- High-performance weathering steel and fire-resistant steel can reduce the maintenance cost of steel structure, and provide new solutions to solve the fire and corrosion problem of exposed unshielded steel structure, such as high-voltage electric tower.

- The production and installation process of fire-resistant weathering steel is basically the same as that of conventional steel, and the design method is the same as ordinary steel structure, but more test verification is needed.

- High-strength weathering steel has been promoted and applied in bridge engineering, and it is necessary to study design theory and method.

- Fire resistant weathering steel can also be used in the floor board

Application in the Expo

The National Pavilion of the Grand Duchy of Luxembourg in the 2010 World Expo in Shanghai, the main building exterior of the museum is rust-colored, because the building materials are a special steel called weathering steel. Weathering steel is also called Cowton Steel. It is special in that it is exposed to the natural environment. With the action of air and rain, the surface of the steel will automatically form a corrosion-resistant protective layer without the need for painting protection. The life of the material is 80. More than a year. Following the use of weathering steel as a building exterior by the Sino-French Center of Tongji University in 2004, the Luxembourg Pavilion was used again. Upon completion, the Luxembourg Pavilion will present the natural primary color of the weathering steel as a whole, and the interior walls of the pavilion will be composed of fir trees. The new weathering steel and natural fir trees create a sculptural castle, which is not only artistic, but also environmentally friendly and sustainable contemporary. At the same time, it also portrays the image of Luxembourg, which is closely related to steel. For more than 100 years, Luxembourg has been known for its superb steelmaking technology. The steel used to build the Eiffel Tower in Paris was from Luxembourg. The weathering steel used in the Luxembourg Pavilion will also be imported from Luxembourg. In addition, the weathering steel that built the entire Luxembourg Pavilion was 100% recyclable after the pavilion was demolished.

GET IN TOUCH

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!