cutting steel

Steel plate cutting using gas flame (oxygen-natural gas) preheat the metal will be cut to be able to burn ignition, and then release the high pressure oxygen flow, make further dramatic metal oxidation and formation of combustion slag blowing off cutting process.

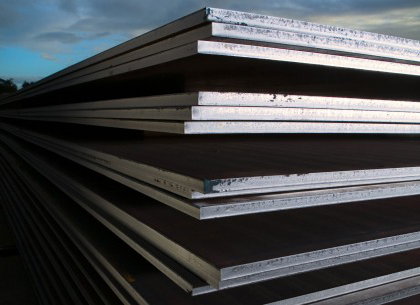

For cutting steel plates shall be approved by the quality unit check acceptance, all indexes meet the specification of the corresponding provisions of the State.

Plate blanking plate should be checked before grade, thickness and surface quality, such as steel plate negative deviation of surface corrosion occurs at depths exceeding national standard parts are not allowed to use the product. The small area of the thickness of the pitting without thinning design cases, welding and grinding until they can be used.

When cutting surface quality of steel grades, specifications and must be checked, after making sure that no doubt can be material.

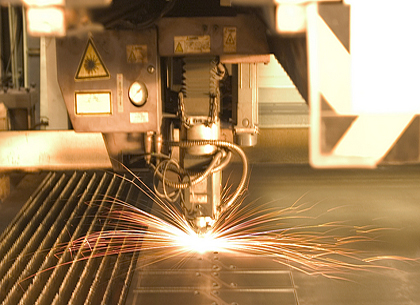

STEEL CUTTING TOOLS

Laser cutting:Laser cutting machine can cut stainless steel 4mm, add oxygen to the laser beam cutting 20mm thick carbon steel, but oxygenated after cutting in cutting thin oxide film is formed. Maximum thickness of cut can be increased to 20mm, but the size error of cutting parts.

Wire cutting:EDM wire cutting short linear cutting. It is in the electric spark perforations, developed on the basis of the forming process of. It not only makes the EDM applications have been developed, and some has been replace by EDM perforation and processing.

Shearing machine:Shears through to the movement of the upper blade and a fixed lower blade by using the proper blade gap, imposed on a variety of thickness of sheet metal shear, break the plate according to the size required separation.

Plasma cutting machine:Plasma cutting is the use of heat to make the work of high temperature plasma arc cut metal parts or partial melting (and evaporation), and through the plasma's momentum out of molten metal to form a processing method of incision.

Ultra high pressure water-jet cutting:Ultra high pressure water-jet cutting, also known as hydro-jet and water-jet, it is plain water after a multi-stage booster to generate the high energy (380MPa) stream, through a very fine Ruby nozzles (φ 0.1-0.35mm) to kilometers per second speed jets, this cut is called ultra high pressure water cutting.

GET IN TOUCH

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!